Shipping isn’t free. At least not for shippers. For them, it’s about carefully managing transportation costs at all points in the order delivery cycle.

Even as parcel demand continues to push shipping costs up at twice the rate of inflation, consumers increasingly expect free shipping, as well as fast and on-time delivery. For eCommerce players, costs are measured in shopping cart abandonment, customer attrition, and margins. By using multi-carrier shipping APIs across the enterprise, merchants can realize the best of both worlds: customer loyalty and reduced costs.

The average global cart abandonment rate for all industries in Q3 of 2018 was 76.9 percent, with retail coming in 75.8 percent, according to SaleCycle, which specializes in helping retailers recover lost sales. Furthermore, according to a study by Baymard Institute, an independent web usability research institute, a whopping 55 percent of people said they abandoned their carts due to extra costs including shipping.

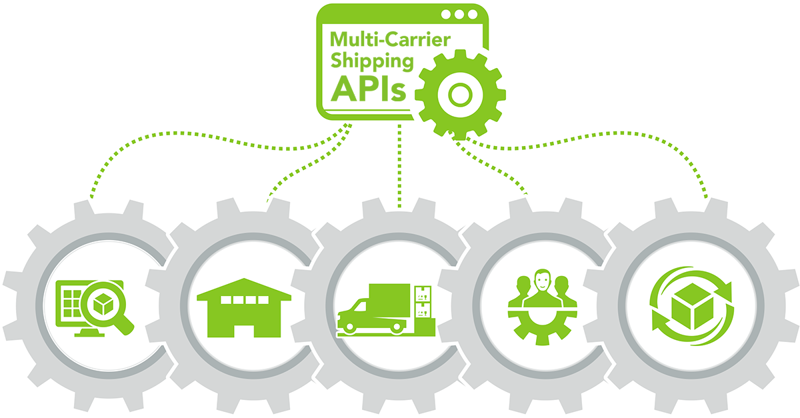

Increasingly, operations and IT managers are working together to incorporate the use of multi-carrier shipping APIs to automate transportation cost control processes within their enterprise systems.

Here are the five best use cases that management should consider when investing in multi-carrier shipping APIs integration development:

1. Order Management Systems: Shoppers want to know cost and delivery options early on in the checkout process. Order management and eCommerce platforms can programmatically call APIs to rate shop carrier costs and delivery times. APIs with cartonization algorithms will instantly and precisely determine the most transportation cost-effective packing, taking into account SKU weight and dimensions, business rules, as well as available carton sizes and carrier services.

2. Warehouse Management Systems: It comes as a surprise to many that most WMS systems do not take transportation cost into account when determining the best way to pack or palletize orders. Pierbridge’s Transtream API can take the guesswork out of the process by instantly calculating the best way to fulfill an order, saving time and shipping costs while reducing waste.

3. Ship from Store and Supplier Portals: Shippers are trying to ship from inventory locations closest to their customers to reduce shipping costs and speed up delivery. Others are seeking to provide an endless aisle of inventory by shipping from suppliers. In either case, look for APIs that can determine shipping costs for multiple carriers from any ship from location, while automating packing instructions, label printing, and pickup requests.

4. Customer Service Management: Multi-carrier tracking APIs can provide customers with proactive updates on delivery times and, more importantly, any exceptions to a shipper’s delivery promise. Augment APIs by embedding widgets in your customer service website to automate self-help order tracking.

5. Returns Management: Shippers are using APIs to automate returns processing. A self-help returns process that lets customers print their own return labels (routed to the appropriate disposition center) from your website is convenient for customers and provides the perfect opportunity for upselling and SEO optimization.

APIs can have an impact on costs and customer experience throughout the order lifecycle. Make sure your developers are satisfied with ease of implementation, documentation, and support of shipping APIs. There is a real benefit to working with the right technology partner that can help you access all the carrier services you need.

Having the right tool for the job, and in this case, the right shipping API, can help shippers streamline operations and cut costs. And, having the best technology partner for shipping APIs can make the process smoother. To learn more about finding the best technology partner, download our eBook “10 Things to Look For in a Perfect Parcel Shipping Technology Partner.”