eCommerce isn’t all about retail. Manufacturers are taking on more of a B2C role as they are called upon to ship directly to eMerchant customers, on top of having to manage an increasingly complex supply chain. And traditional TMS systems aren’t equipped to untangle that complexity.

It may be an understatement, but shipping has become very complex for manufacturers.

“It’s kind of crazy,” says Mike Graves, Director of Product Management at Pierbridge, after walking through an example of how in just three years, shipping changed drastically for a Pierbridge client.

It was a company that manufactures generators, selling through a national home improvement store. Up until three years ago, its traditional model had always been: get an order from the store, ship in bulk to the store’s distribution center every month, and then the generators would be distributed to the stores. Customers bought the items and drove them home. “So it was really easy – they would get a purchase order, make a shipment, done.” Simple.

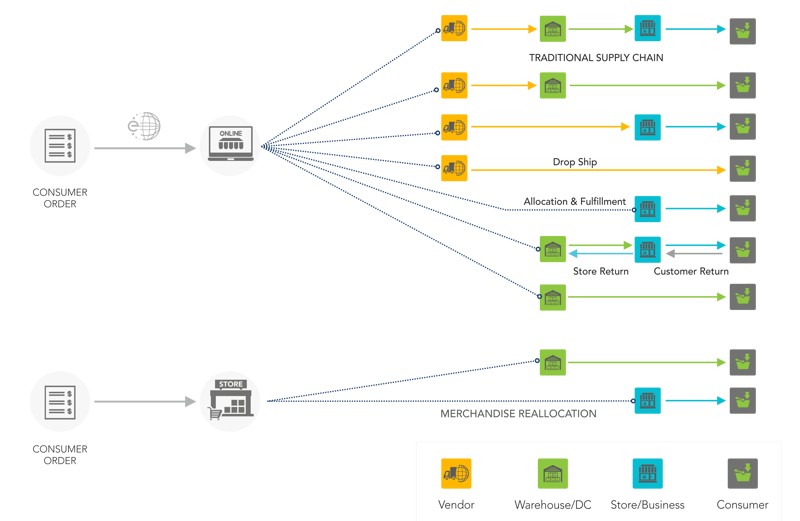

Not so much anymore. “The store started changing its business model to omni-channel distribution to accommodate consumer demand for faster delivery. In addition to shipping orders to DCs, it needed to ship much smaller orders in quantities of one or two to 400-plus stores. So it had to figure out how to change its model to start shipping hundreds of smaller shipments out to these individual stores.”

And then it became more complex. Like most retailers, the home improvement store stocked the product in, say, the Northeast stores but not in the Southeast. Consumers expected goods to be transferred between stores. “That’s something stores didn’t have to worry about before. That evolved to ‘Okay, we now want to be able to take orders and have them drop-shipped directly to the consumer. So now you have a 200 lb. generator that’s not going to be able to go via UPS. Freight companies like XPO are growing like crazy, offering last-mile white glove services that deliver goods across the threshold of a home. Increasingly, freight companies are thinking more than last mile, they are thinking ‘last inch’.”

Now omni-channel fulfillment is extending to suppliers. Instead of shipping eCommerce orders to DCs, suppliers have to ship directly to consumers or to a store location near a consumer to meet the demand for faster delivery. And then you have all of the parts and accessories that are being fulfilled directly from suppliers by freight or parcel service.”

So yeah, “it’s kind of crazy.”

The other problem? Traditional TMS’ that manufacturers have invested in are not equipped to handle the new complexity.

“The traditional TMS systems that manufacturers have invested in are designed for that traditional freight transaction and not for smaller parcel shipments,” explains Graves. “Their optimization logic doesn’t take regional parcel, couriers, or white glove freight services into account. Pure eCommerce players like Wayfair and Overstock are now sending furniture that’s bigger than what UPS would deliver. It’s not something a traditional LTL would back up to the bay doors and deliver. You have to have things like lift gates and drivers trained to deliver to a house, same-day. These are all areas that the traditional TMS providers are not designed to handle.”

Add on to that increasing competition, rising transportation costs eCommerce has created across all industries, compliance regulation, driver shortages, international shipping, and a multitude of other factors. Oh, and let’s not forget about the snowball-that-just-won’t-quit-getting-bigger, aka Amazon.

And that’s just the tip of the iceberg, as manufacturers will attest. Regardless, it’s a lot to take on, so we asked Graves for a few key pieces of advice he regularly shares with Pierbridge’s manufacturing clients when they are upgrading their TMS.

Key #1: Sweet, cost-saving fruit

“Tackle the low-hanging fruit and don’t try to take it all on at one time. You’ll get into these projects that can never be delivered. What are 20 percent of the issues to be solved that will drive 80 percent of the cost out of the network? And then just continuously improve over time. Tackle a little bit, but also invest in a system that can scale and grow with you and hit all those long-term needs. Don’t feel like you have to do it all at once. It’s just constantly evaluating and adjusting.”

Key #2: Don’t throw out your expensive TMS

Just because those trusty, traditional TMS’ weren’t built to navigate the new complexity doesn’t mean manufacturers should retire them. “Multi-carrier parcel solutions don’t have to be substitutional to what they have, they can be complementary. We can integrate with those TMS’ and provide those functions and complement what they already made huge investments in.” Think integrating through APIs, directly into shopping carts, customer service, and package tracking.

Key #3: The team behind the software

Experience counts, advises Graves, a 25-year industry veteran and former Marine who has boots-on-the-ground experience managing shipping operations and then managing shipping system software products at Pitney Bowes. “You are not just purchasing software, you are buying into a team that has decades of experience, that knows the direction of where the industry is headed, and can eliminate the gotchas. We were parcel before it was cool,” adds Graves with a laugh.

Key #4: Eliminating manual processes

Where are you likely losing productivity? Probably wherever there are time-consuming manual processes. Also, notes Graves, “exception processing, where a manufacturer has a traditional TMS and suddenly parcel is the exception, so they have to figure out how to manage that, how to improve it. Suddenly you have all these exceptions lanes and tons of manual work to make sure it goes out.”

Key #5: Reverse logistics

Another big challenge is reverse logistics. “Something like one in three shipments gets returned in eCommerce, so now you have to handle reverse logistics. A returns app can generate all the labels and minimize your costs on return. Depending on the item, you may want it to get to the customer in one or two days, but you may not be concerned with how fast it comes back, and you can take different routes coming out than you did going in.”

Key #6: Leverage your volume and look for new opportunities

Software, like spend management, business intelligence, analytics, and third-party audit to ensure you’re getting billed accurately, can help you leverage your volume in a way to get the best discount,” says Graves. “And then being able to constantly look at your data and for new opportunities, potentially for things like drop-ship. As an example, say you have a bunch of product leaving New York for California. Instead of sending 100 individual boxes, put them on two pallets and send it as an LTL shipment to California and then it can be broken up and delivered to the final mile with a local low-cost carrier as opposed to sending it by air out of New York.”

It’s a lot, we know. And it looks to only be getting more complex. Maybe you’re already dealing with it, maybe it’s on your to-do list. But luckily, technology has evolved to help navigate modern supply chain demands and challenges.